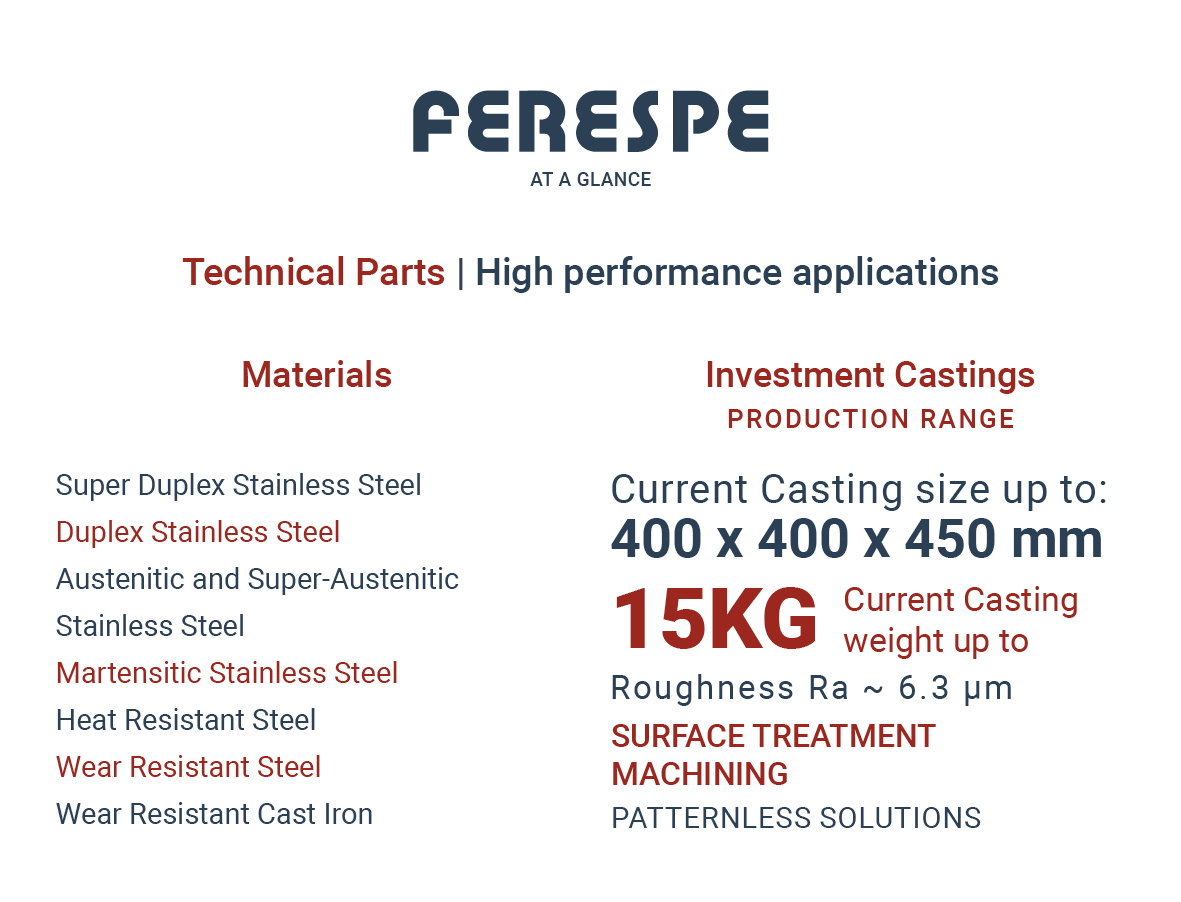

To fulfil the increasing demand for dimensional accuracy and better surface finish, FERESPE offers a complement of range – Investment Casting -, keeping the same focus on small and medium series niche market.

Dedicated to produce technical parts for high performance applications, FERESPE uses the following alloys:

– Duplex, super duplex and super austenitic stainless steels

– Medium and low alloyed steels

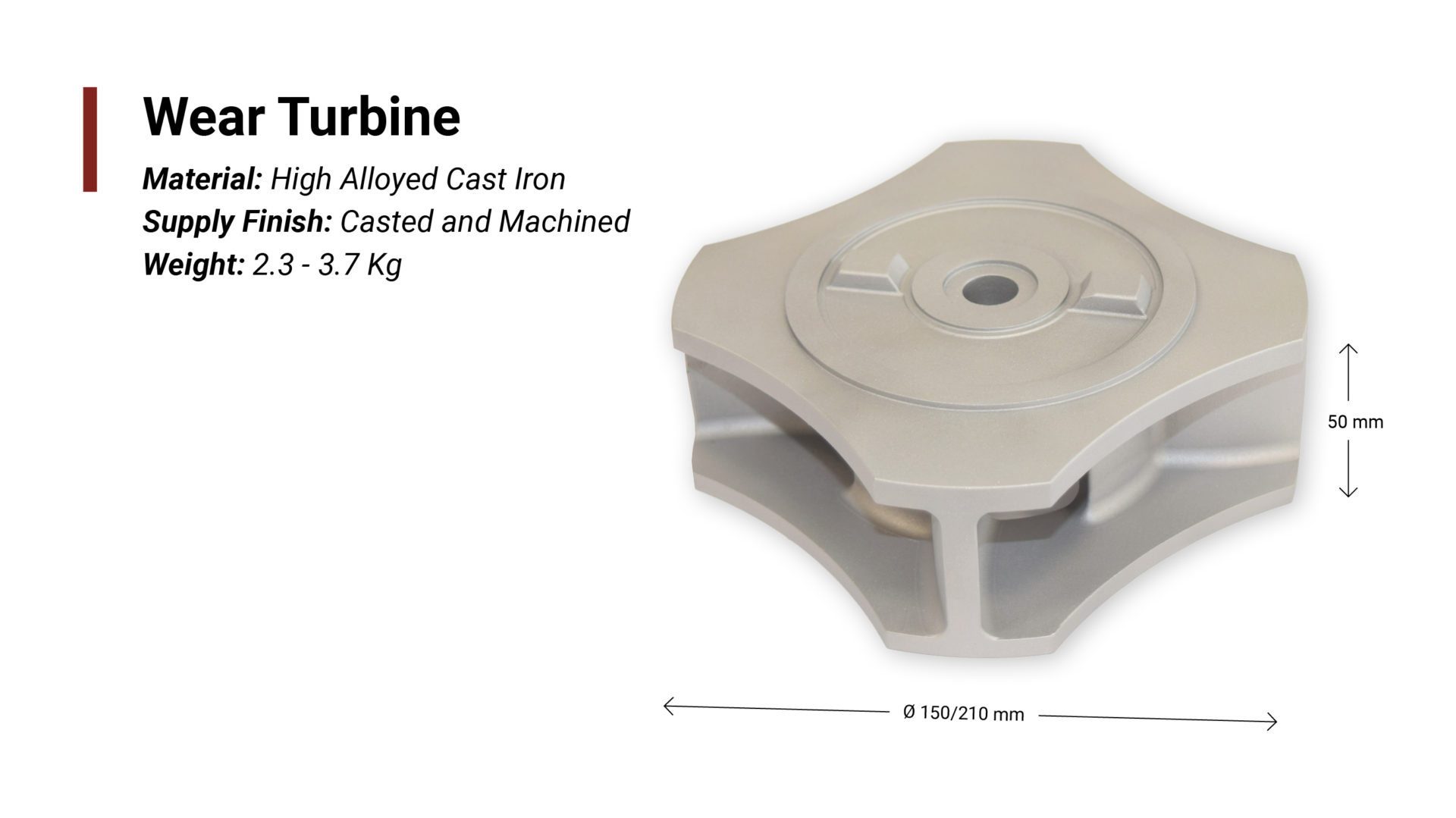

– High alloyed cast irons

About 90% of our production is exported to several different industrial sectors.

Investment Casting uses a wax or dispensible pattern to make a mould. After being attached to the gating system, the wax “tree” is dipped into a refractory slurry forming a ceramic shell. This ceramic shell is then heated to melt and remove the wax, as well as to improve mechanical properties. Finally, the molten metal is poured into the ceramic shell cavity to cool down and solidify.

Main Characteristics of Investment Casting:

- Smaller castings

- High Dimensional Accuracy

- High Roughness Quality

- High Complex shape and near net shape design, if compared with Sand Castings

MATERIALS

Certifications &

Qualifications

– ISO 9001:2015

DNV

– NORSOK

Code M-650 Rev. 4 – Duplex

and Super Dupex SS

– Pumps & Valves

Framatome – KTA 1401

ASME NCA 3800

– Pressure Equipment

TUV NORD – PED 2014/68/EU

and AD-MERKBLATT W0/TRD 100

– Austenitic Stainless Steel

Lloyds Register

– Railway Industry

D8

TUV NORD – EN 15085-2

– Marine & Offshore Division

Bureau Ventas – BV Mode II Scheme ABS

– Ships

DNV – Steel Castings

– ISO 14001:2015

DNV

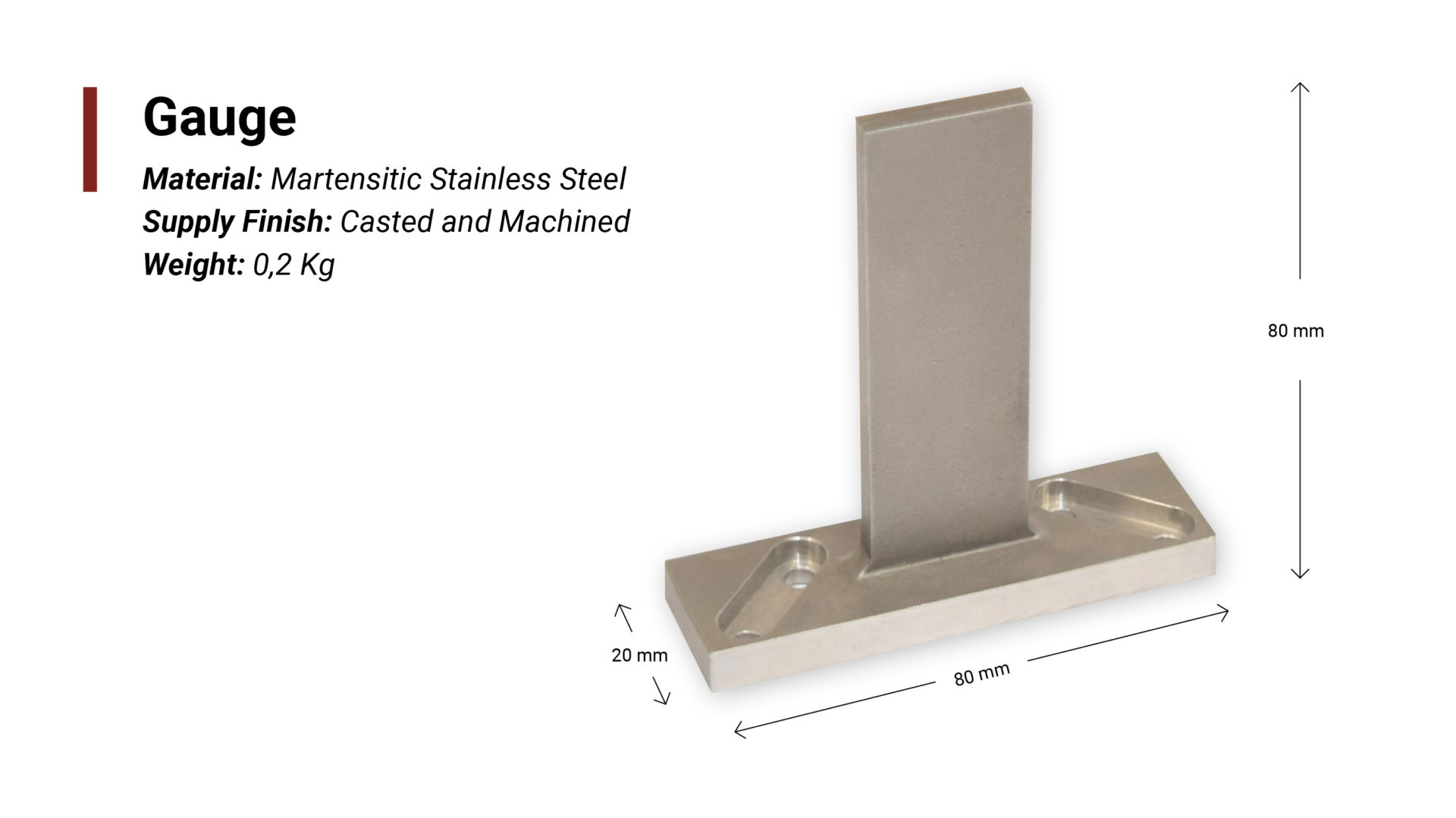

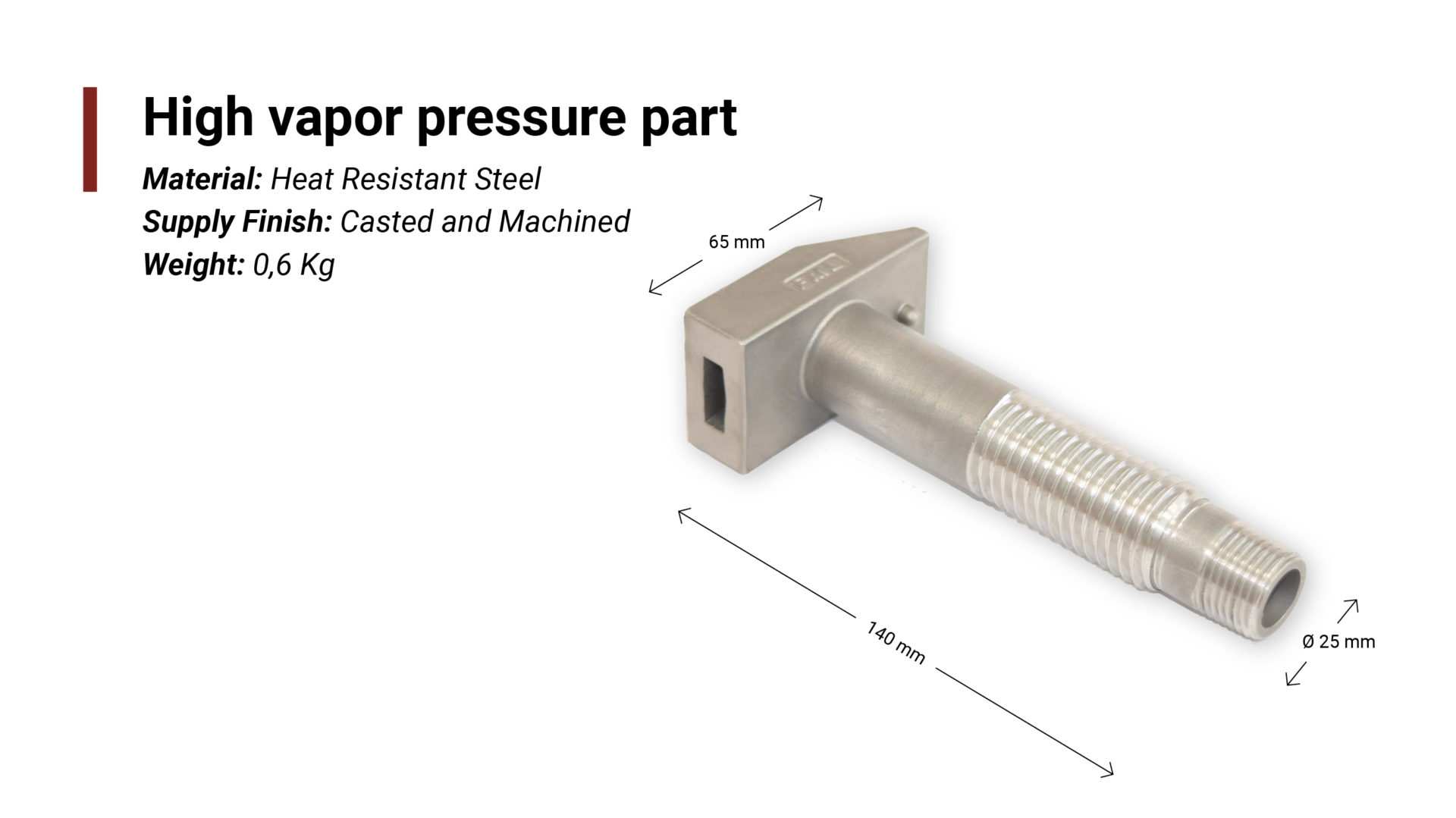

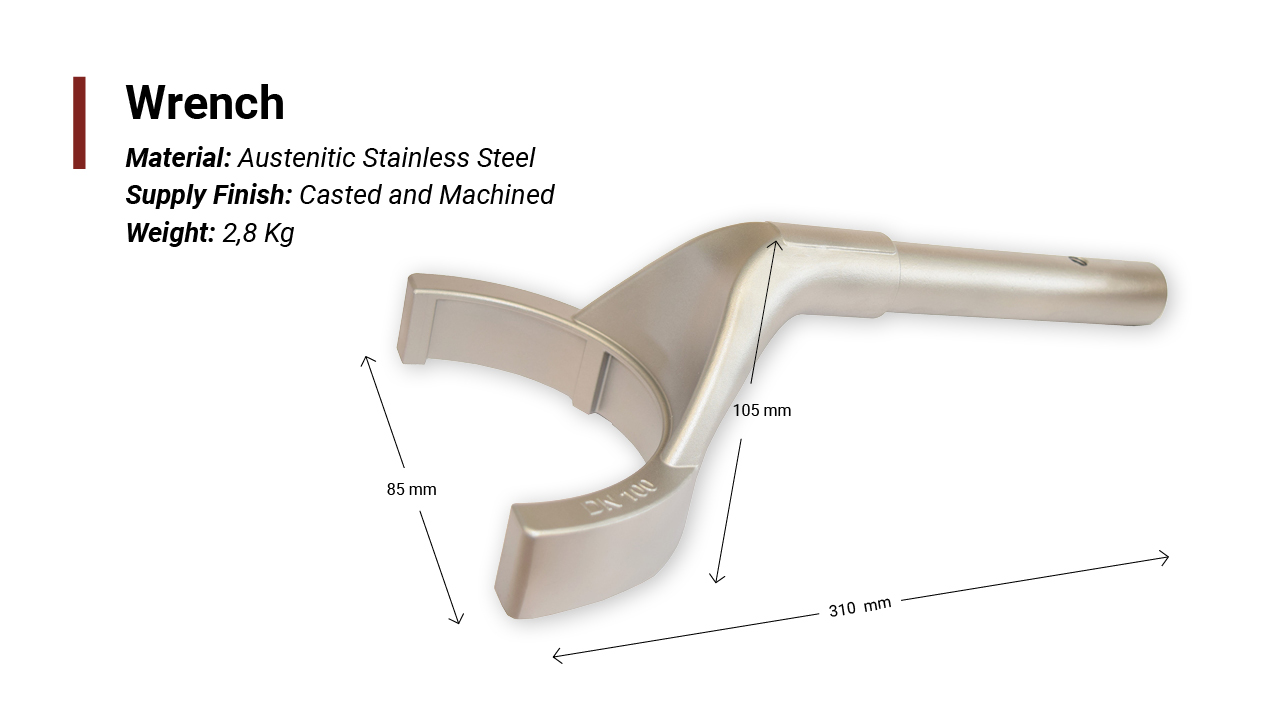

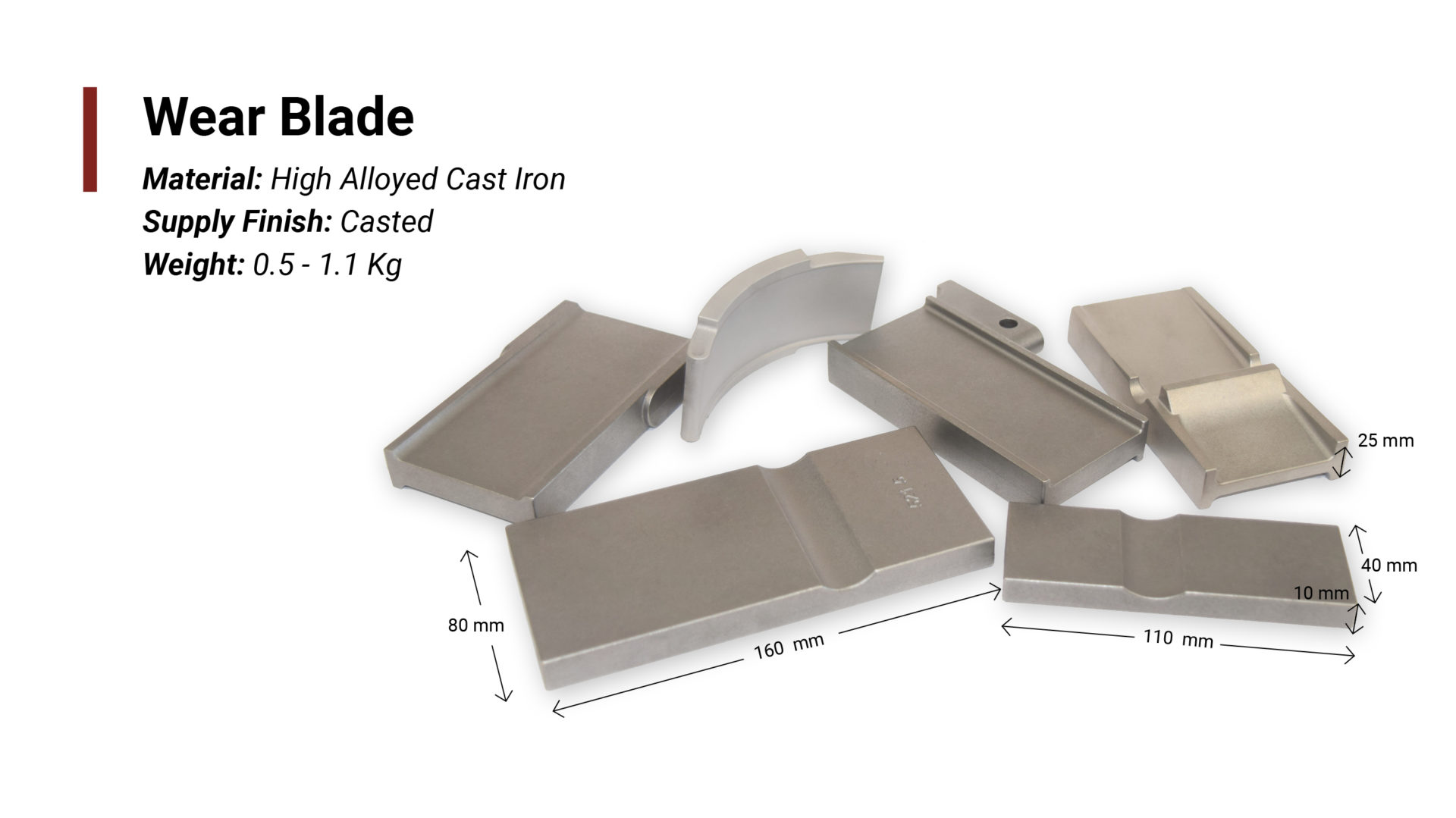

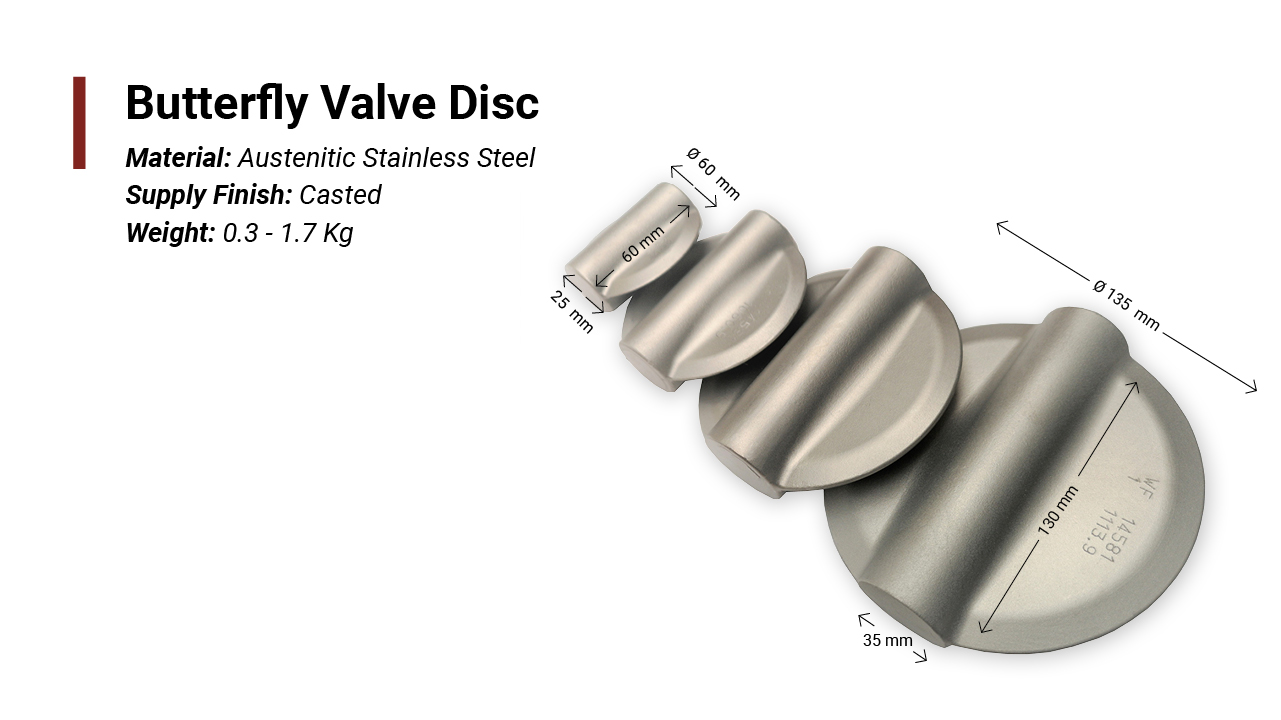

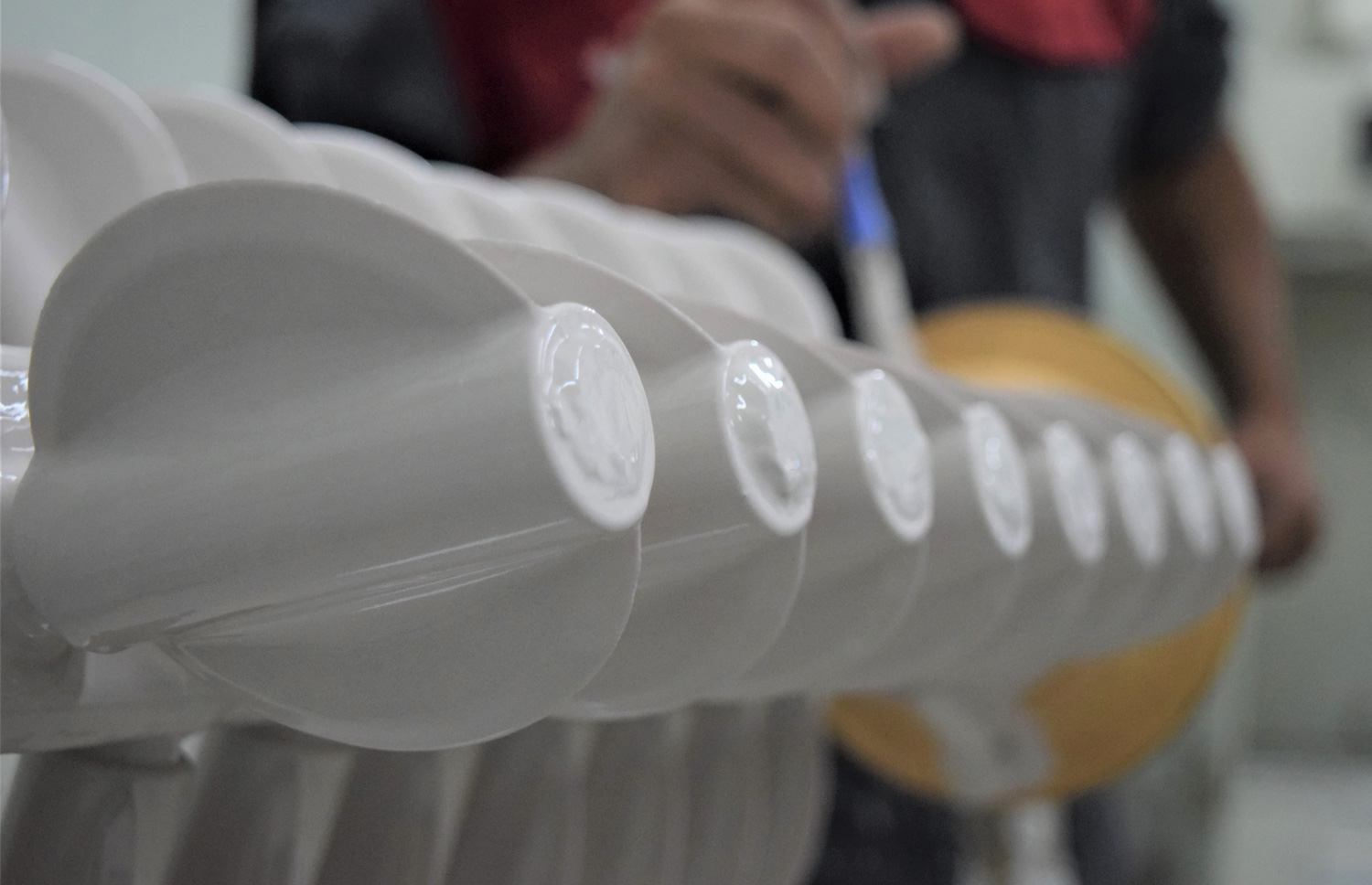

Parts (Examples)

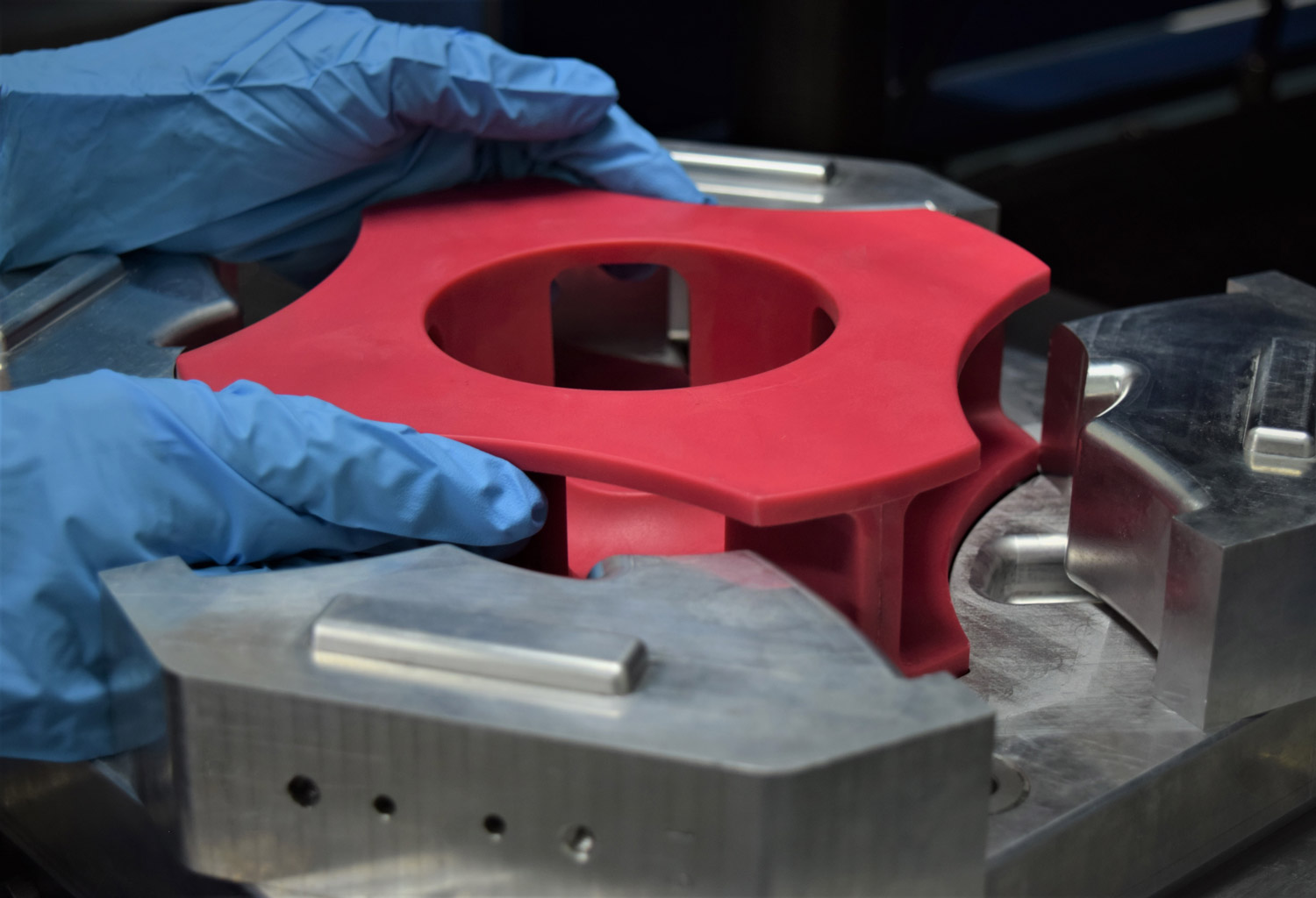

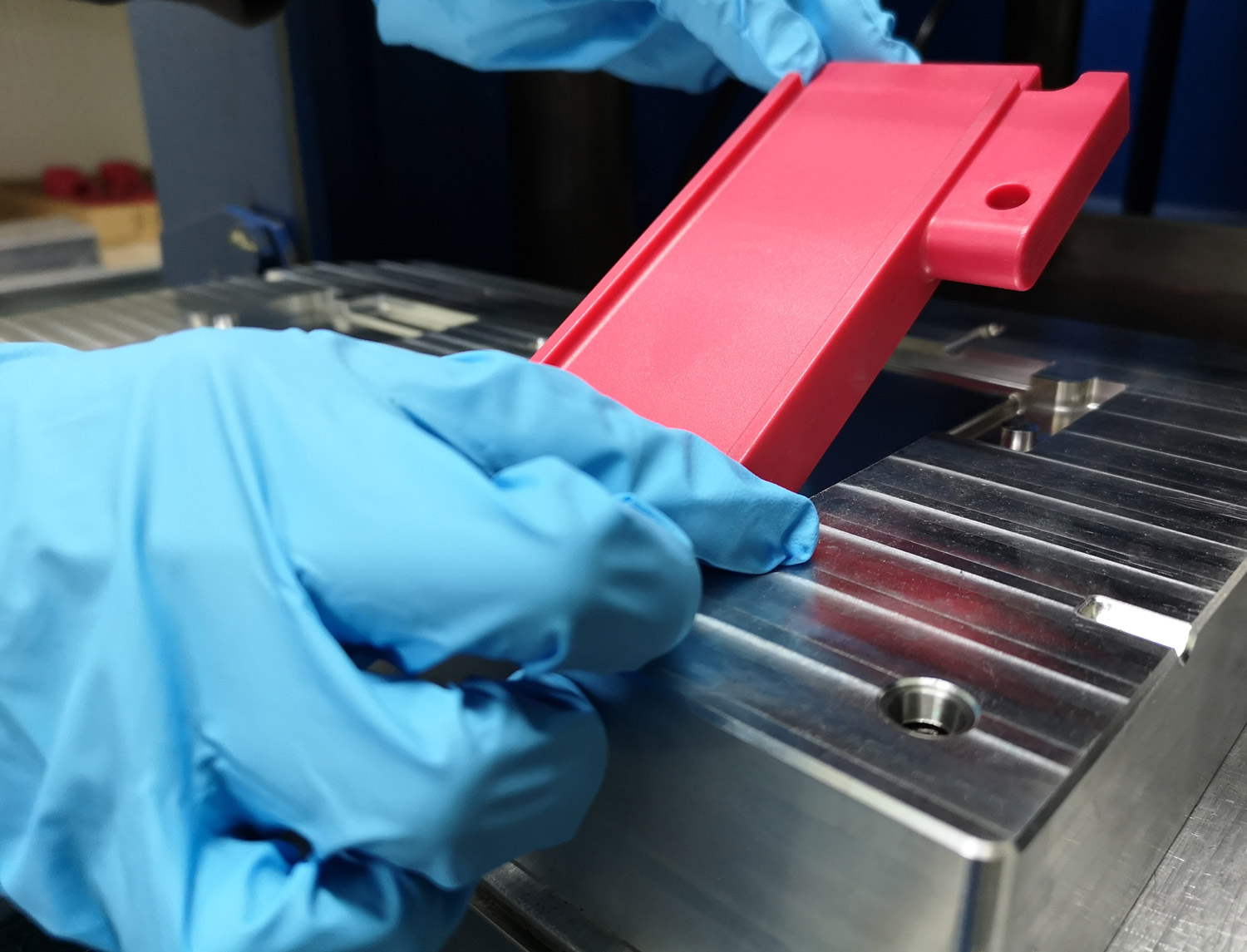

FERESPE In Action at Investment Casting Unit

HOW IS DONE

Phase I — Wax injection

In the investment casting process, the first step is the design and manufacturing of the mould into which wax pattern is injected. This pattern is developed in-house through additive manufacturing technique – SLA Rapid Prototyping – or made by machining of aluminium block by FERESPE’s reliable subcontracted partners.

As any imperfection on the wax pattern will appear on the casting, the surface quality of the mould and wax pattern has a critical importance on the quality of the casting. FERESPE uses 3D Photometric Scanning System to assure its dimensional and geometric accuracy.

After the wax injection, the resulting model will have the same shape as the final cast piece. It is then assembled onto a “tree” consisting of one or various models and the feeding and gating system.

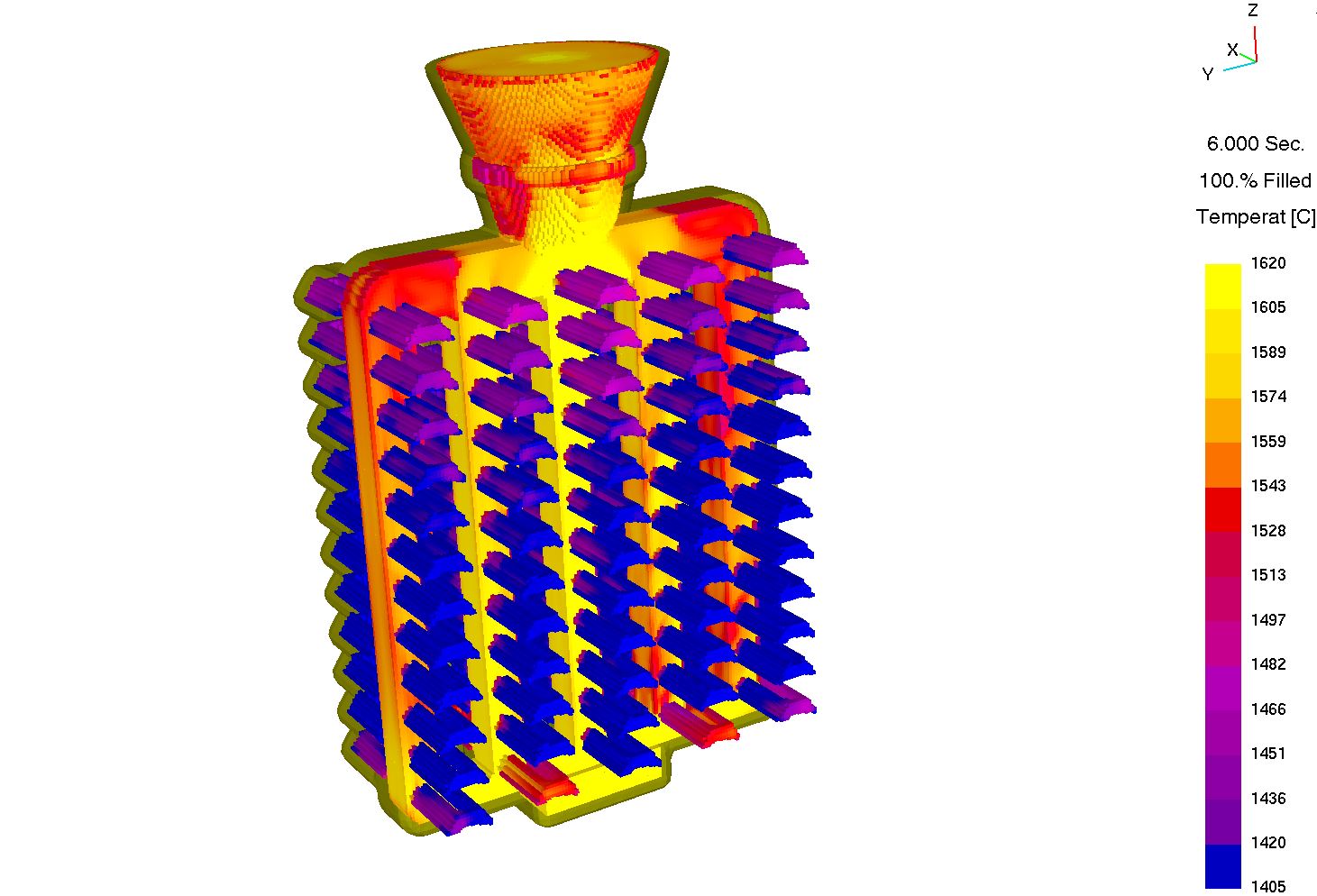

Phase II — Ceramic Coating, Dewaxing and Melting

The most important step is to build the ceramic coating around the “tree” which consists of various layers of different slurries and sands.

After this, the shell is then dewaxed and will be heated to temperatures up to 1100ºC. At that time, the ceramic shell is ready to be pre-heated and have metal poured.

Phase III — Finishing Process

FERESPE performs the finishing processes, such as surface treatments (grinding and shotblasting), heat treatments and final inspections. Other activities, such has machining, coatings, surface chemical treatments, among others, can be subcontracted to FERESPE’s experienced partners.

Plant

Product Engineering

Wax and Shell Room

- 400 x 400 x 250 mm maximum pattern dimension

- 600 x 600 x 500 mm maximum slurry tanks

Melting

#3 Induction Furnaces

- #2 induction furnaces of 50 kg

- #1 induction furnace of 150 kg

Finishings

- Shot and sand blasting machines

- CM, NORMFINISH and NORBLAST

- Grinding Machines

- Manual abrasive belt grinder

- Heat Treatments

- In-house heat treatments

- Other activities, such has machining, coatings, surface chemical treatments, among others, can be subcontracted to FERESPE’s experienced partners.

Quality Control Equipment

- Optical Emission Spectrometers

- Destructive Testing

- Non Destructive Testing

- Hardness Control

- Samples Preparation and Metallographic Analysis