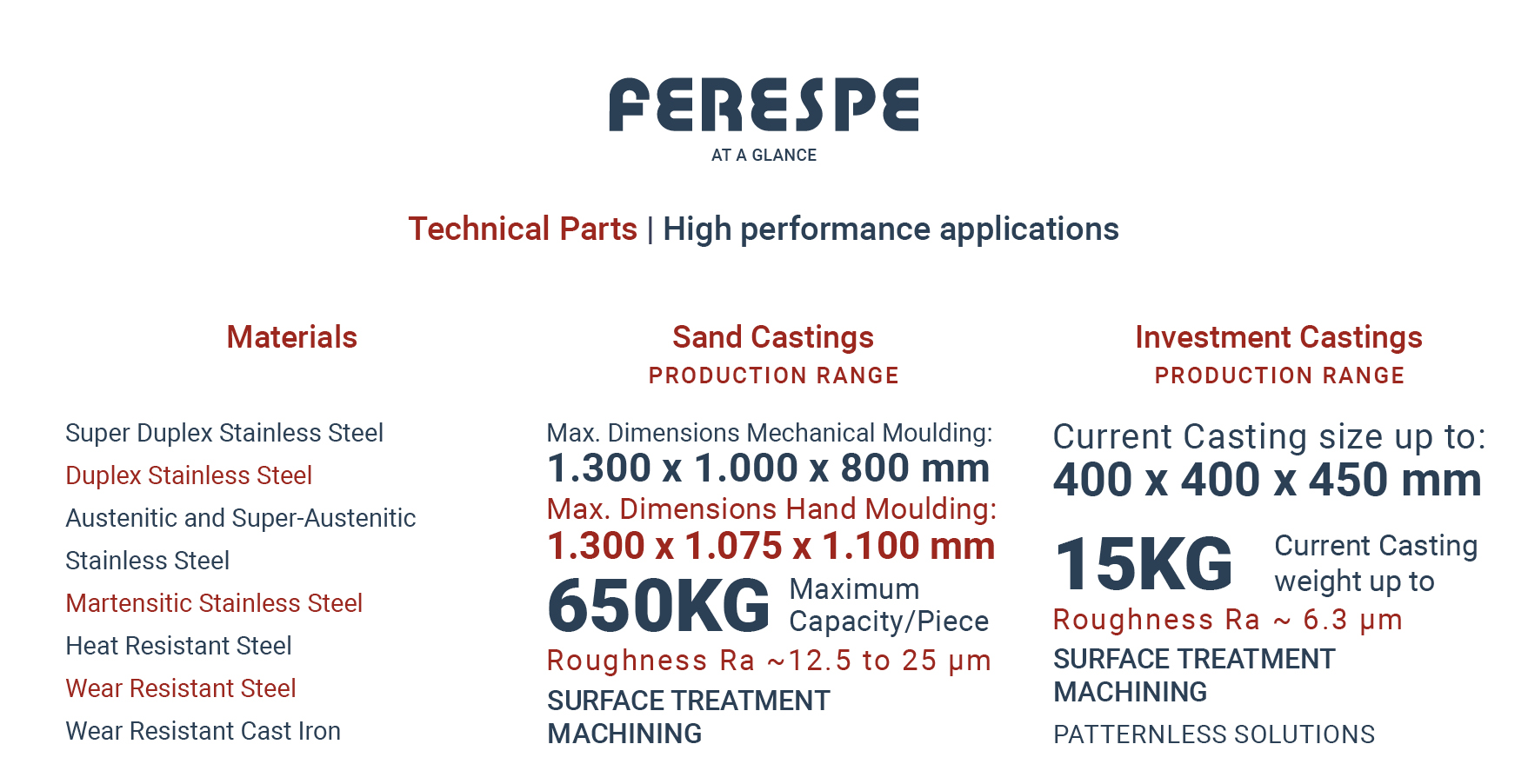

FERESPE is a sand and investment castings foundry producing technical parts for high performance applications, using the following alloys:

– Duplex, super duplex and super austenitic stainless steels

– Medium and low alloyed steels

– High alloyed cast irons

We deliver the most competitive casting solutions on dimensional accuracy and surface finish through constant analysis of both processes to meet the needs of the most demanding customers.

Also we provide a wide range of services in the field of Heat Treatments.

FERESPE exports about 90% of its production to several different industrial sectors and positions itself in a small and medium series niche market.

Our Solutions Your Success

Choose either Sand or Investment Castings as the best technique for your application.

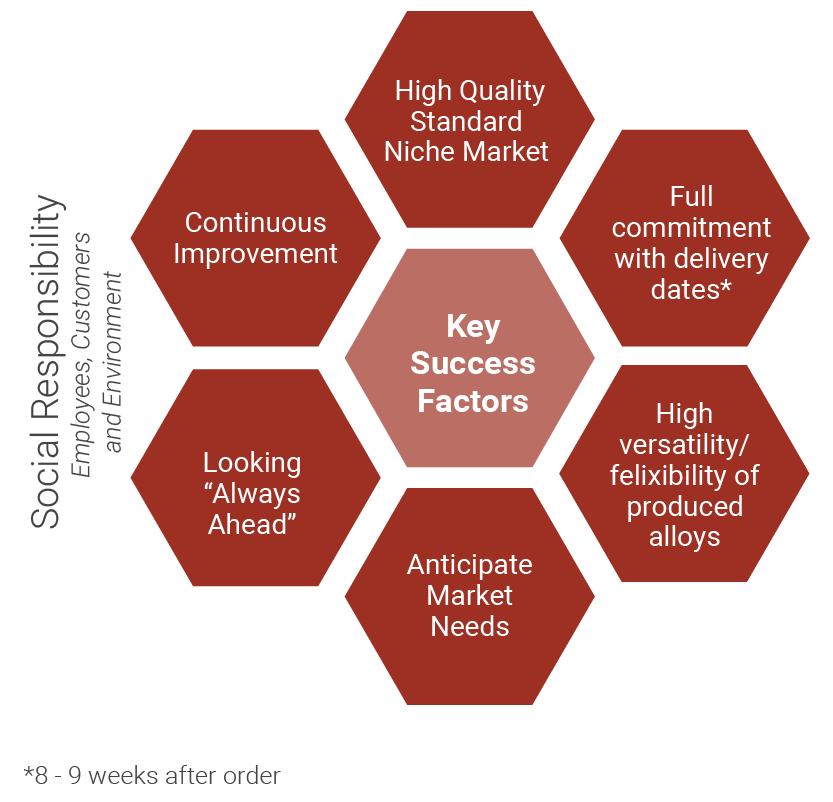

What Makes Us Different

Certifications &

Qualifications

– ISO 9001:2015

DNV

– NORSOK

Code M-650 Rev. 4 – Duplex

and Super Dupex SS

– Pumps & Valves

Framatome – KTA 1401

ASME NCA 3800

– Pressure Equipment

TUV NORD – PED 2014/68/EU

and AD-MERKBLATT W0/TRD 100

– Austenitic Stainless Steel

Lloyds Register

– Railway Industry

D8

TUV NORD – EN 15085-2

– Marine & Offshore Division

Bureau Ventas – BV Mode II Scheme ABS

– Ships

DNV – Steel Castings

– ISO 14001:2015

DNV

Deployment Area

FERESPE is located at Vila Nova de Famalicão, in a total area of 21,926 sqm of industrial land.

In terms of gross building area, FERESPE is divided into 6 major areas, for a total of 7.131 sqm

– Sand Casting: 3.051 sqm

– Mould Warehouse: 540 sqm

– Investment Casting: 500 sqm

– Heat Treatments: 1.247 sqm

– Warehouse: 685 sqm

– Social, laboratory and administrative areas: 1.108 sqm

Organigram & Team

Strategic Positioning

Quality, Environment and Safety Policy

FERESPE Quality, Environment and Safety Policy is directly connected with its Customers and internal and external organizational environment. This being reflected in its Customers and other interested parties Satisfaction as well as in the environmental protection, health and safety working conditions for its Employees.

Our History

- 1980-1990

- 1990-2000

- 2000-2010

- 2010-2015

- 2015-2021

-

1980-1985

1981

– FERESPE is founded by Eng. Jorge Macedo Casais.

– Initiates the production of white cast iron alloy and alloy cast steels.1984

Starts the production of low and medium alloy steel and stainless steel. -

1990-2000

1994

– ISO 9001 certification.

– Established several business relations with Netherlands, France, Austria, Belgium, Germany, UK, Denmark, Sweden, Switzerland, Italy, Norway, Spain, USA…

– Begins a selection of demanding markets such us Railway, Petrochemical, Papermaking pulp.

– Strengthening of relations with the knowledge centers (universities, technological centers, …).

– Supplying pieces with high added value on machining and sub-assembling. -

2000-2010

2004

– Qualifications and certifications in Railways and Energy, Oil & Gas market.

– FERESPE stands out both in a national and international level on the production of technical pieces in Super-Duplex Stainless Steel and Super-Austenitic Stainless Steel.2009

– Jorge Macedo Casais passed away.

– This early disappearance of such a charismatic leader did not cause disturbances in the company, due to his unique management qualities to foresee the future of the company were always there, the testimony was passed serene and carefully. -

2010-2015

2013

– Investment on the areas of molding and thermic treatments.

– Area reserved to the processing of Stainless Steel Casting.2015

– Offer a wider range of technical parts by investing in a casting unit “Investment Castings”.

– A PhD student in an industrial environment with the Oporto University – DEMM and the University of Texas at Austin in Super-Duplex stainless steel.

– The NORSOK qualification process initiated and concluded.

– Preparation of FERESPE for the market of castings Nuclear industry (only power generation, because FERESPE has the principle, since its genesis, to do not work with military industry). -

2015-2021

2016

Energy Market Qualification

– NORSOK

Nuclear Market Certifications:

– KTA 1401

– ASME NCA 3800

Refining Cast Steel – project to develop the decarburization and desulfurization / dephosphorization methodologies.2017

Environmental certification concluded according NP EN ISO 14001:2015.2018

– Start of Investment Casting Production.

– Start of Heat Treatment Unit.2020-2021

Covid 19 – Corporate flexibility skills development.