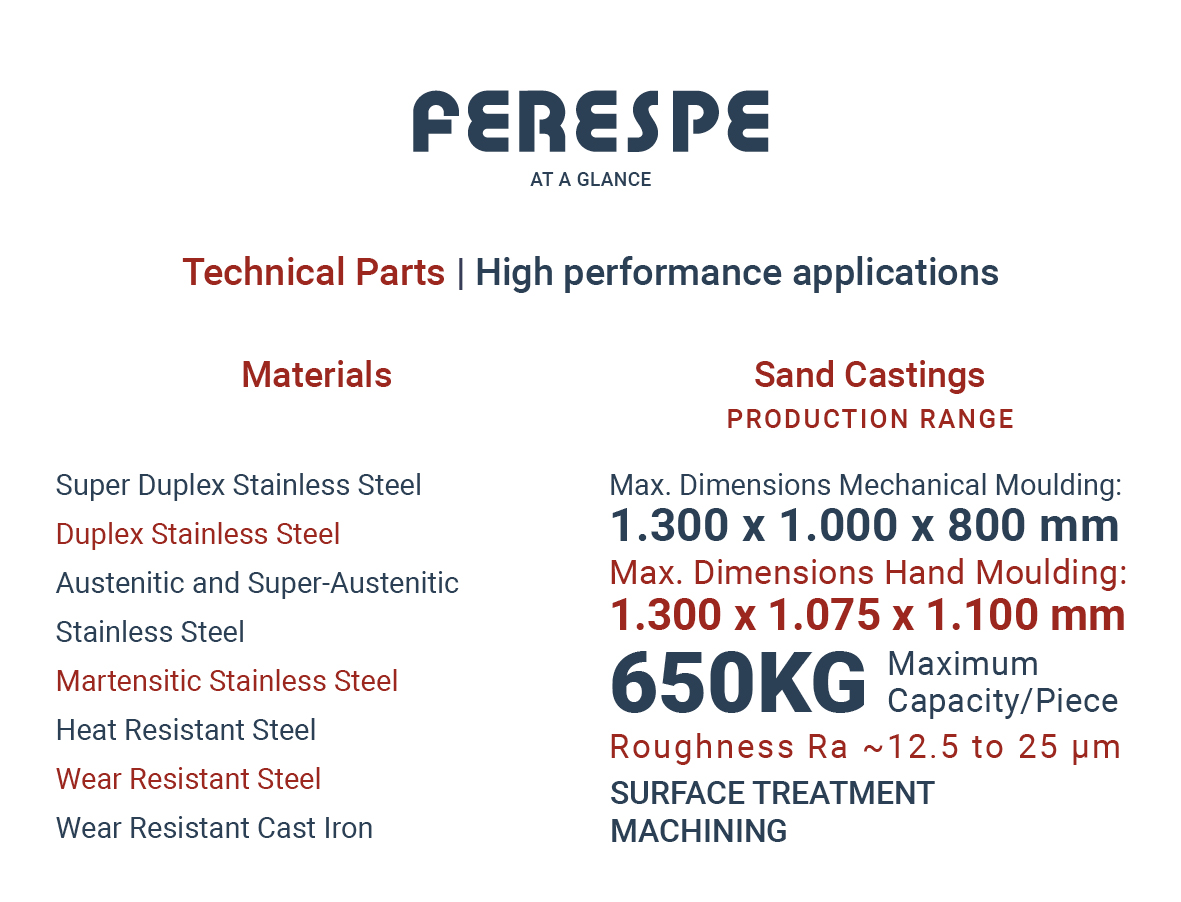

Sand Castings

FERESPE, founded in 1981, focuses on the production of technical parts for high performance applications, using the following alloys:

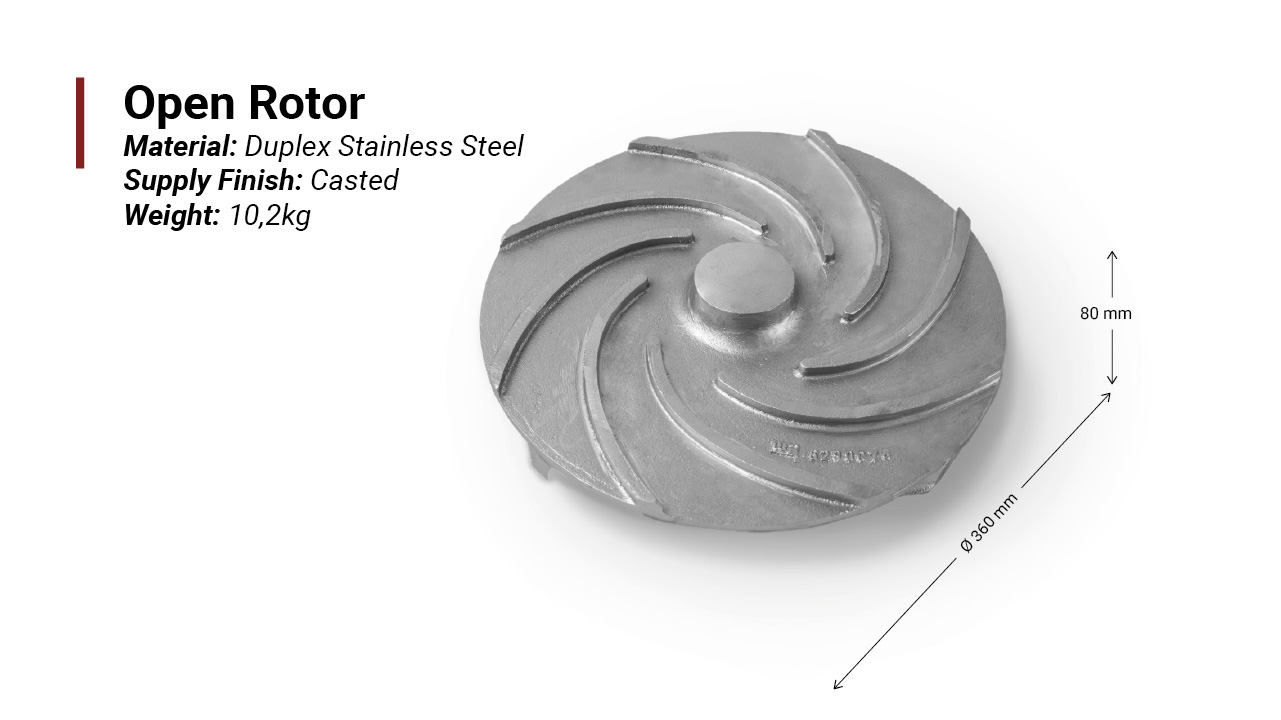

– Duplex, super duplex and super austenitic stainless steel

– Medium and low alloyed steel

– High alloyed cast iron

Exports about 90% of its production to several different industrial sectors and positions itself in a small and medium series niche market.

Sand Castings uses a silica-based material to create a moulding surface. After achieving the required chemical composition, the molten metal is poured into a mould which has the desired shape cavity to cool down and solidify .

Main Characteristics of Sand Casting:

- Larger castings

- Good Dimensional Accuracy

- Good Roughness Quality

- Complex shape and near net shape design, if compared with forging or metal worked pieces

MATERIALS

Certifications &

Qualifications

– ISO 9001:2015

DNV

– NORSOK

Code M-650 Rev. 4 – Duplex

and Super Dupex SS

– Pumps & Valves

Framatome – KTA 1401

ASME NCA 3800

– Pressure Equipment

TUV NORD – PED 2014/68/EU

and AD-MERKBLATT W0/TRD 100

– Austenitic Stainless Steel

Lloyds Register

– Railway Industry

D8

TUV NORD – EN 15085-2

– Marine & Offshore Division

Bureau Ventas – BV Mode II Scheme ABS

– Ships

DNV – Steel Castings

– ISO 14001:2015

DNV

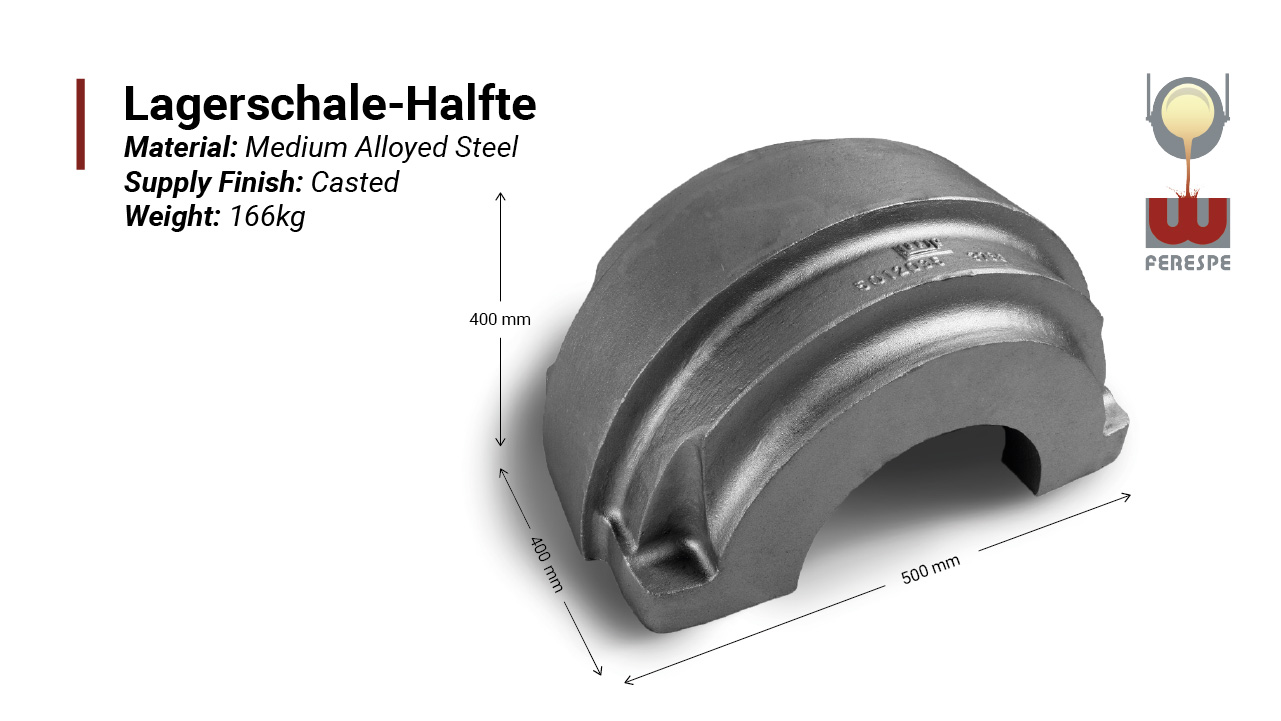

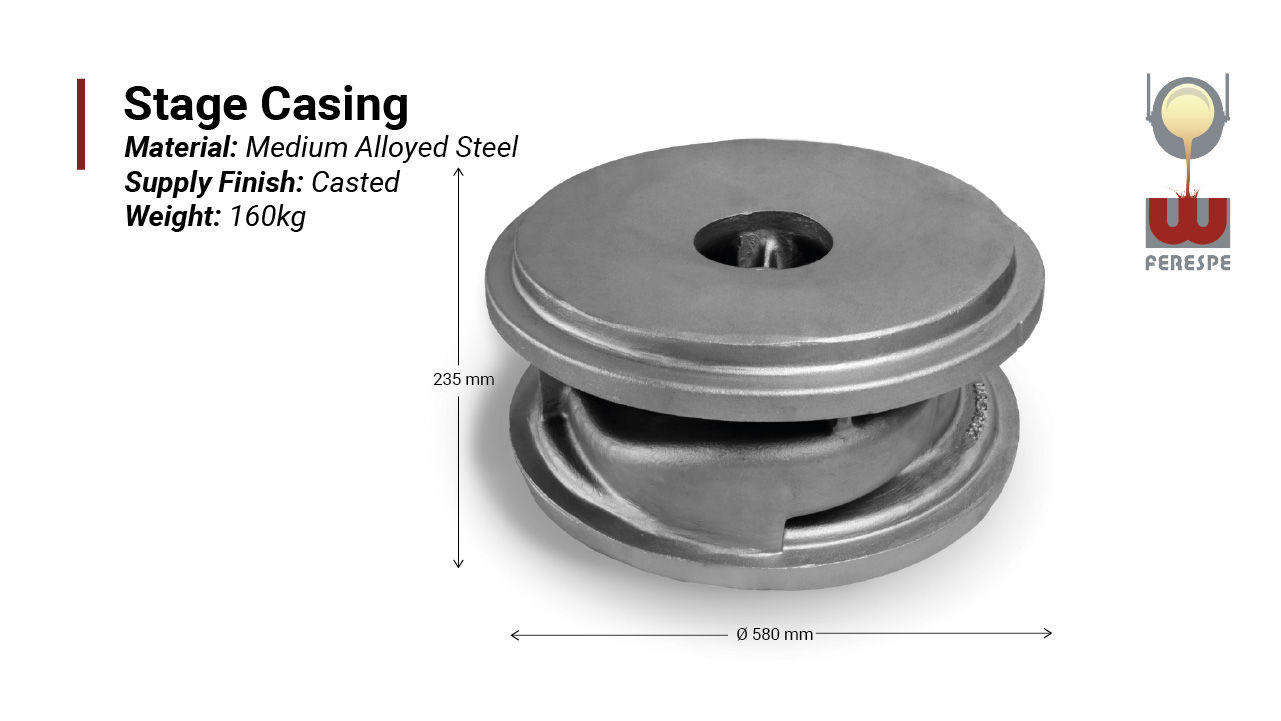

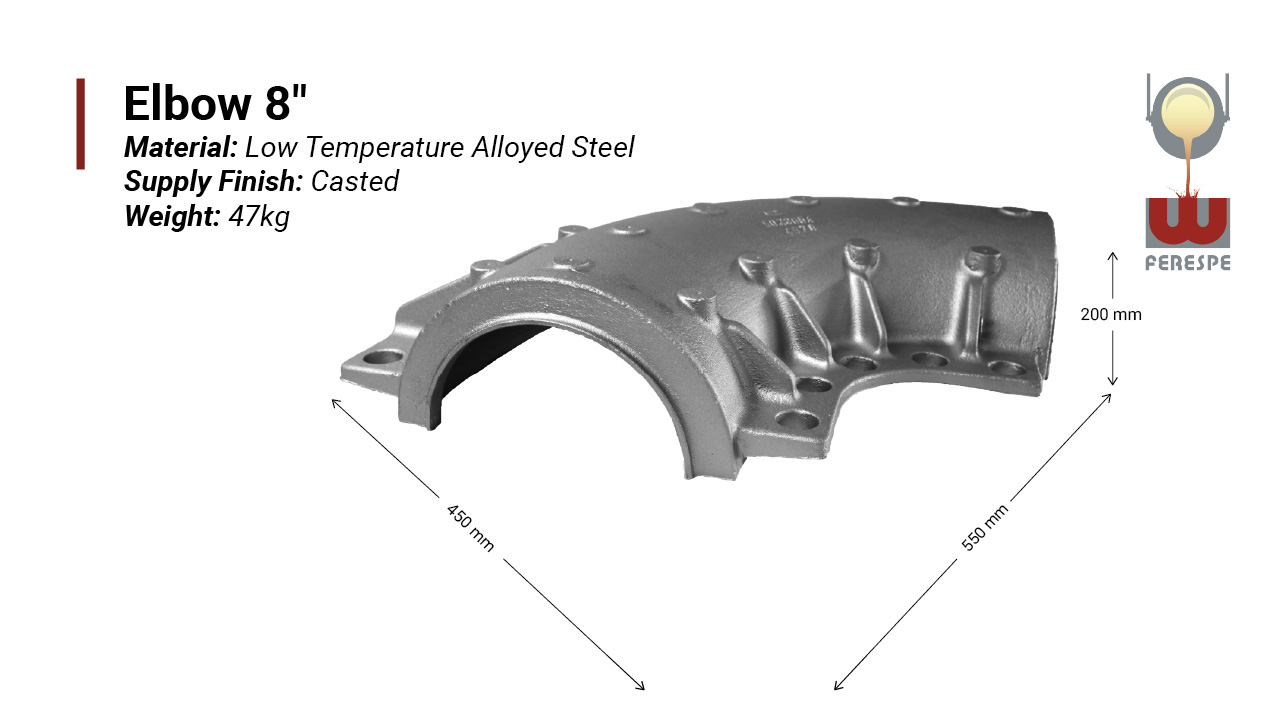

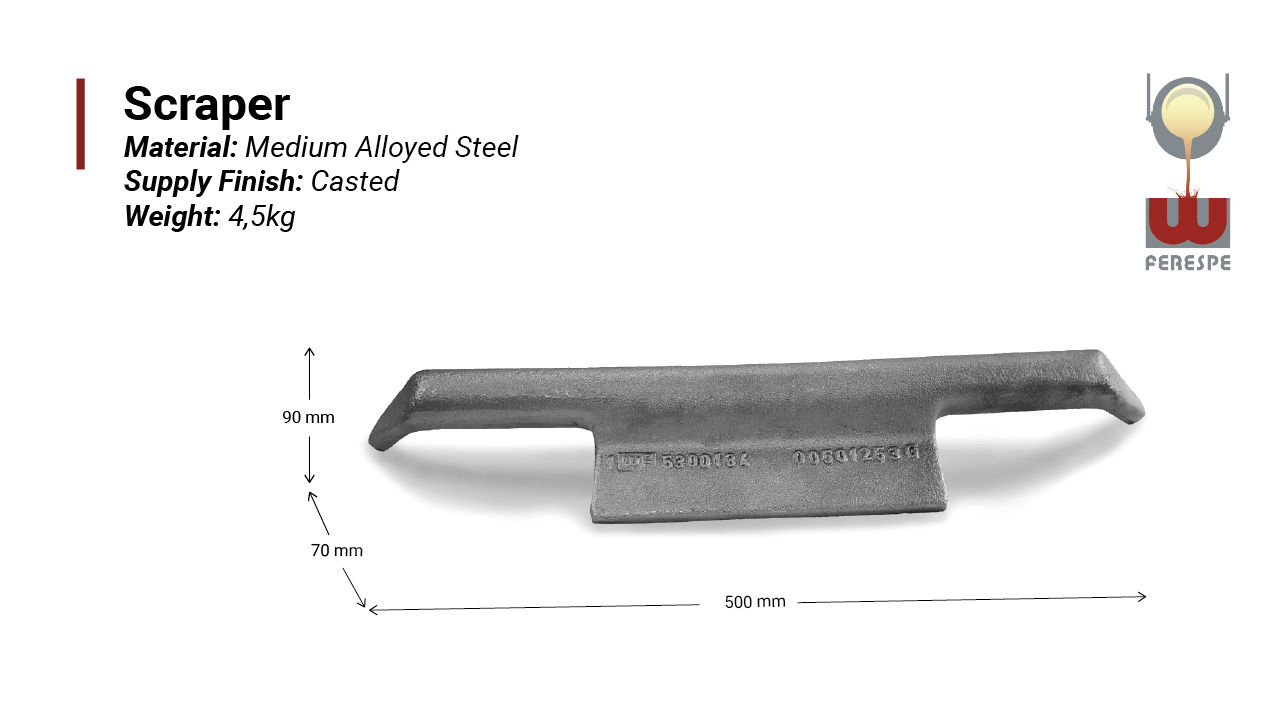

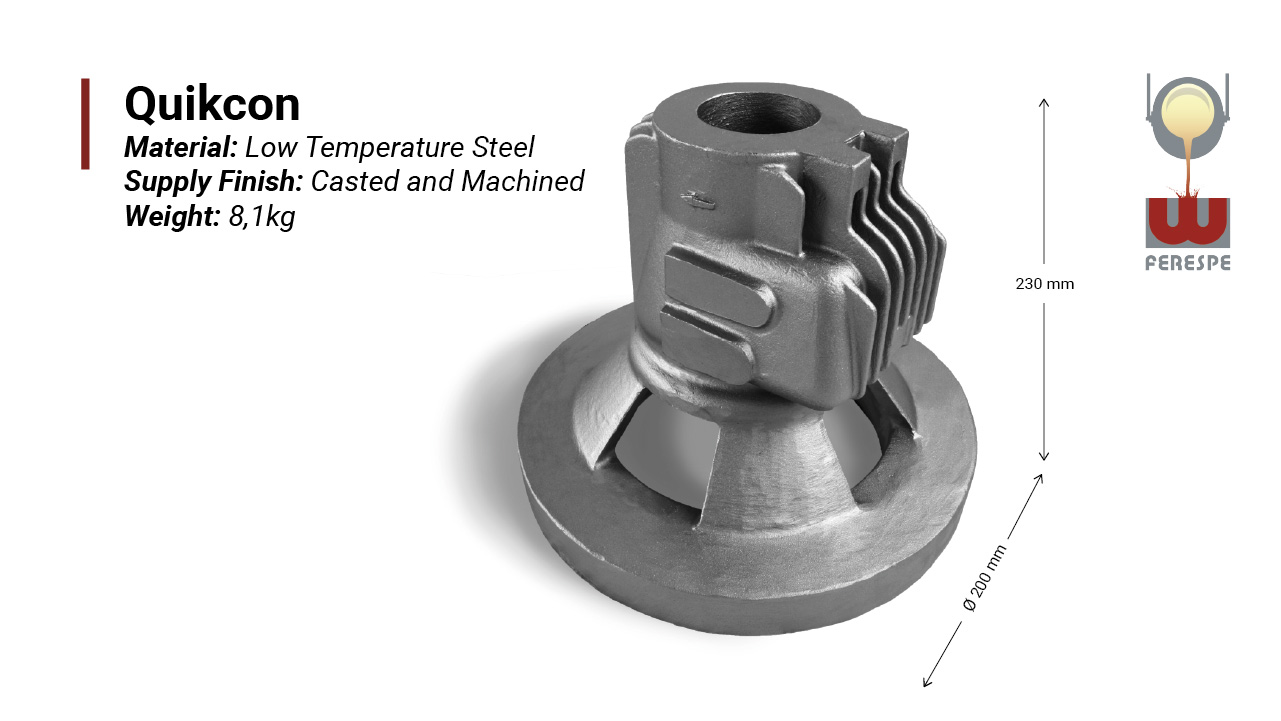

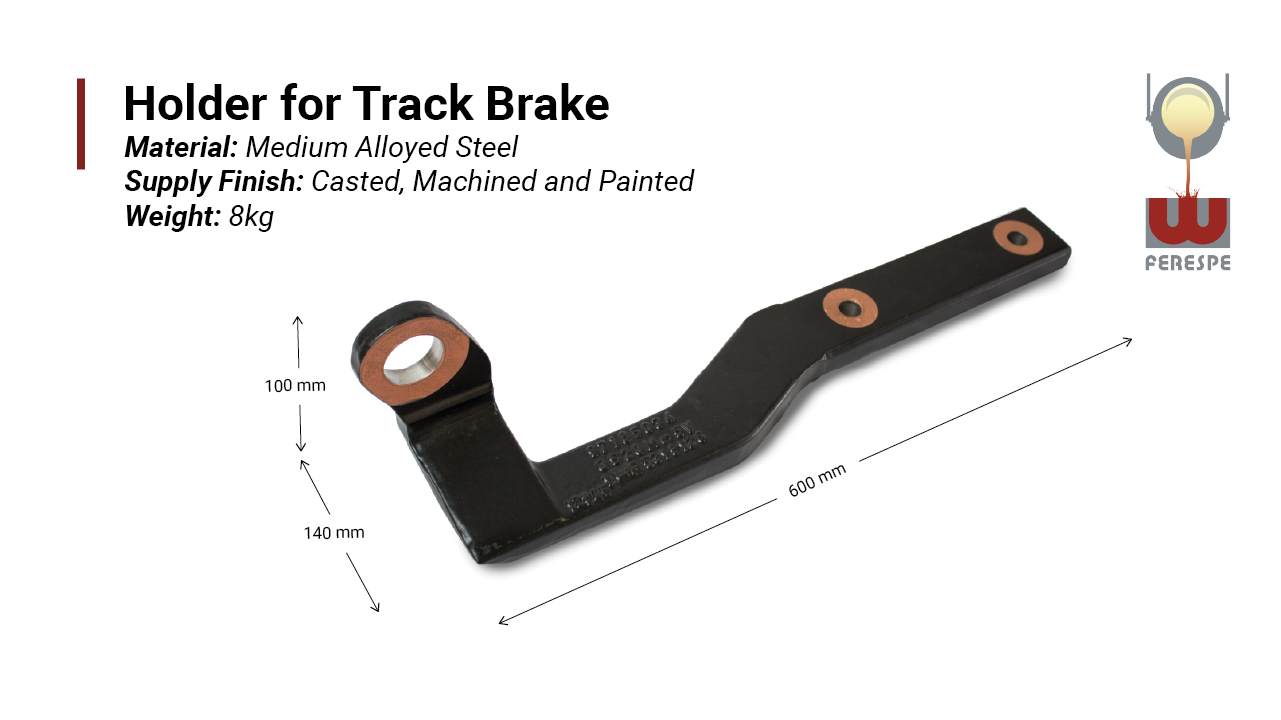

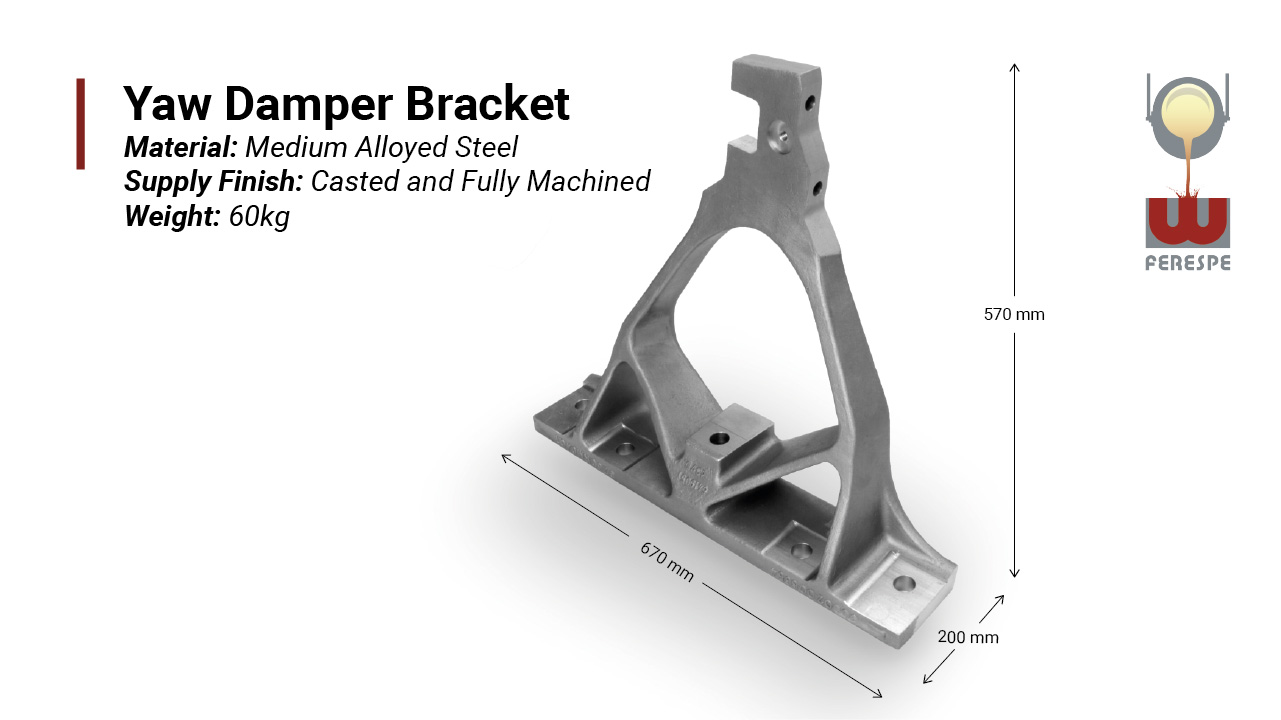

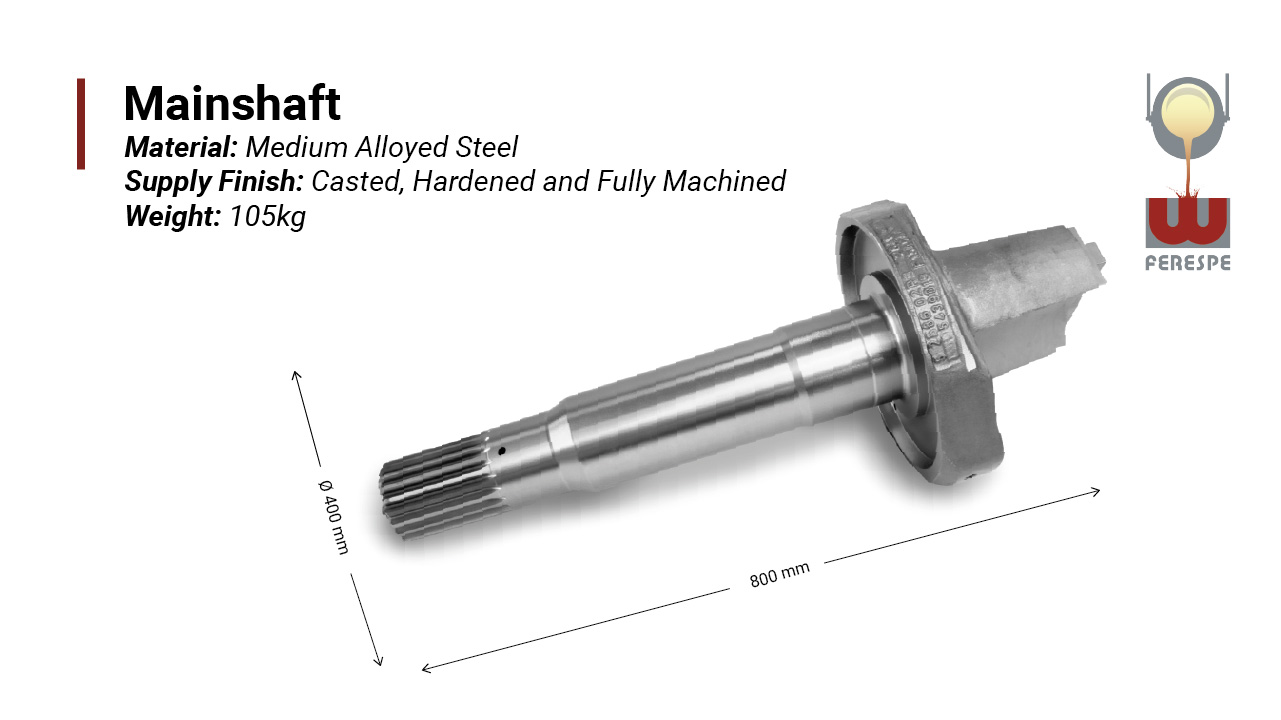

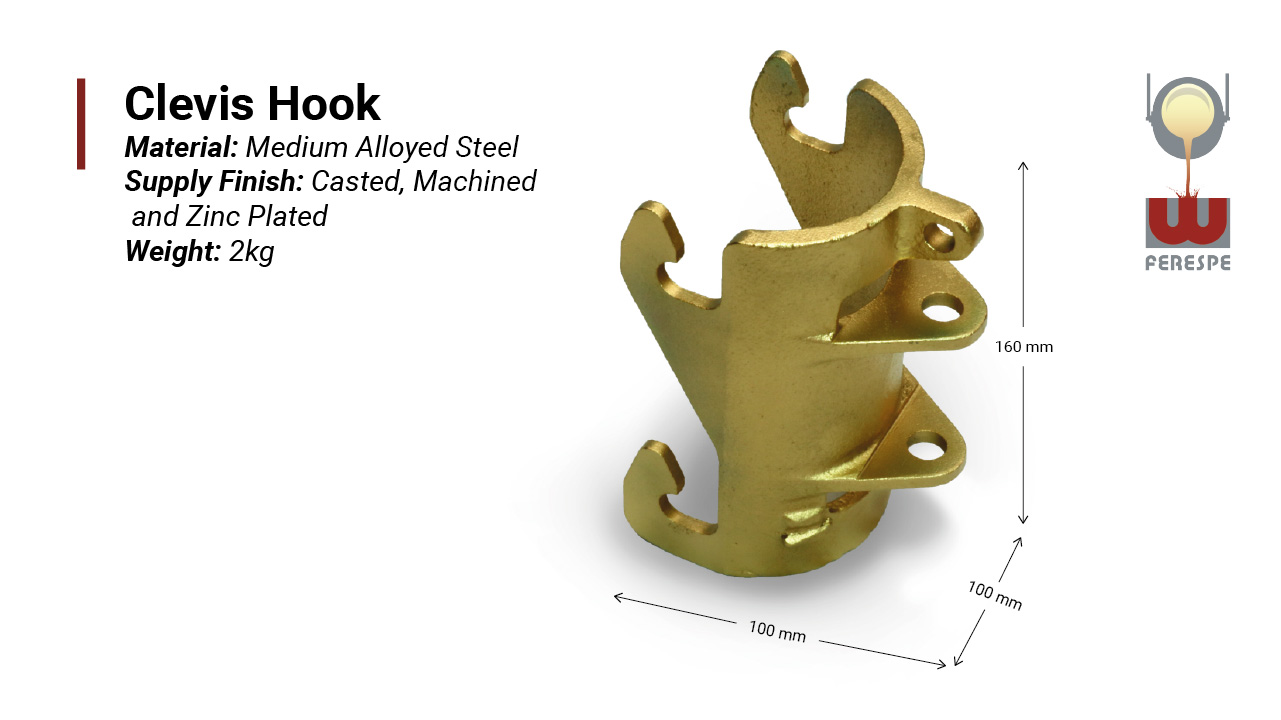

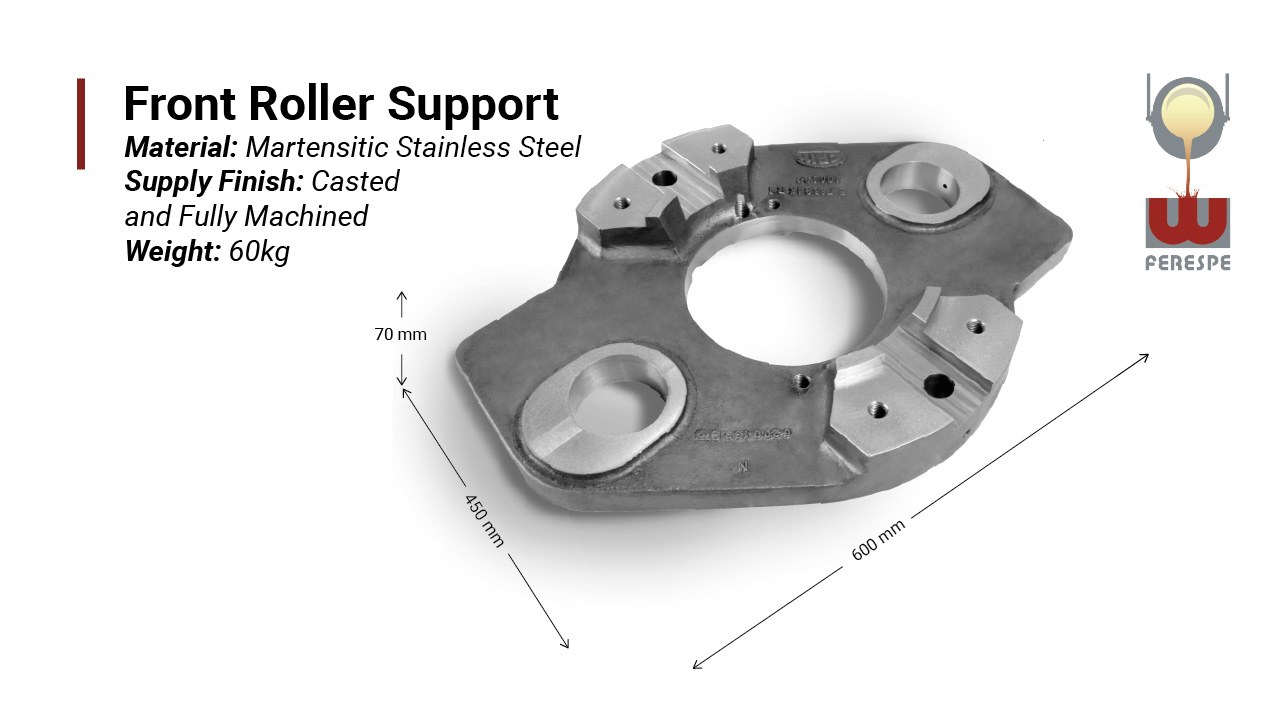

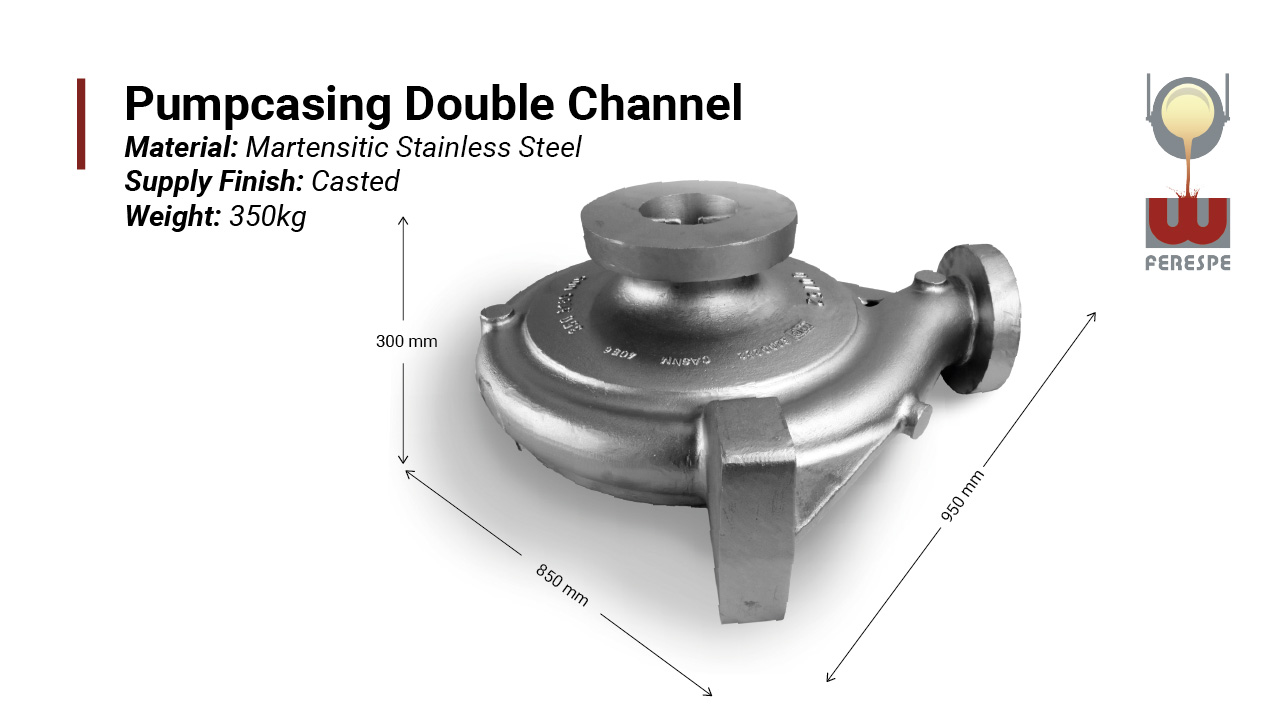

Parts (Examples)

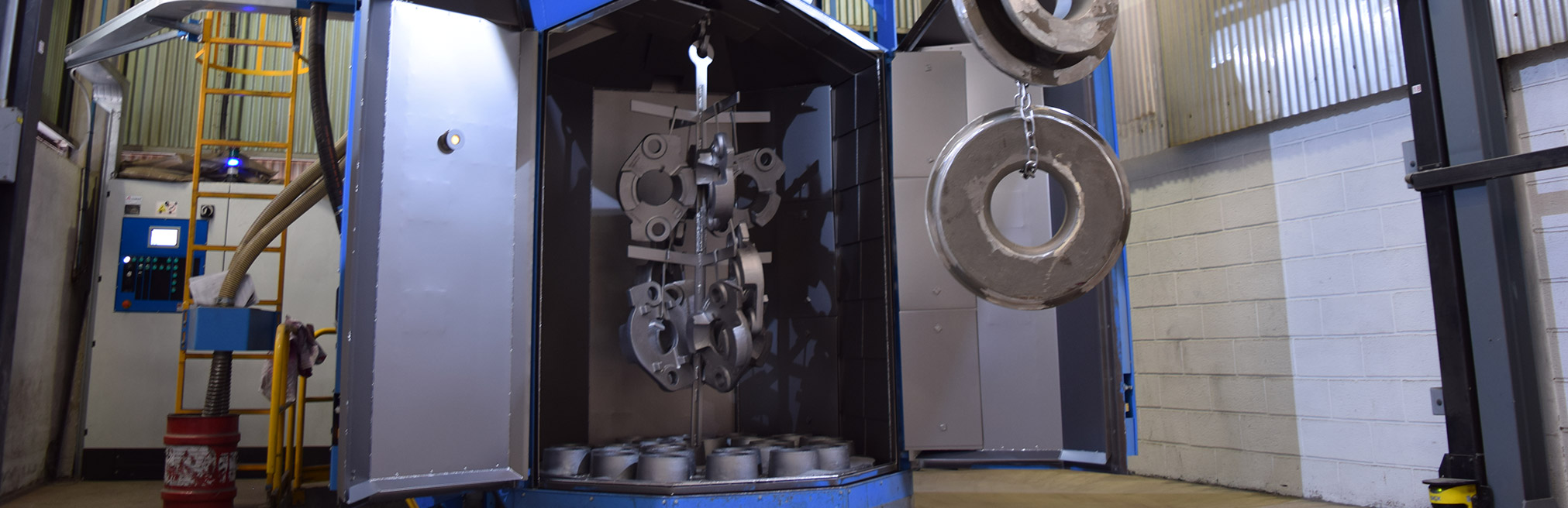

FERESPE In Action at Sand Casting Unit

Office

Production

Quality Control

Finishings

Plant

Product Engineering

- Modeling

- PTC Creo 3.0

- 3D Scanning

- Dimensional Control

- Reverse Engineering

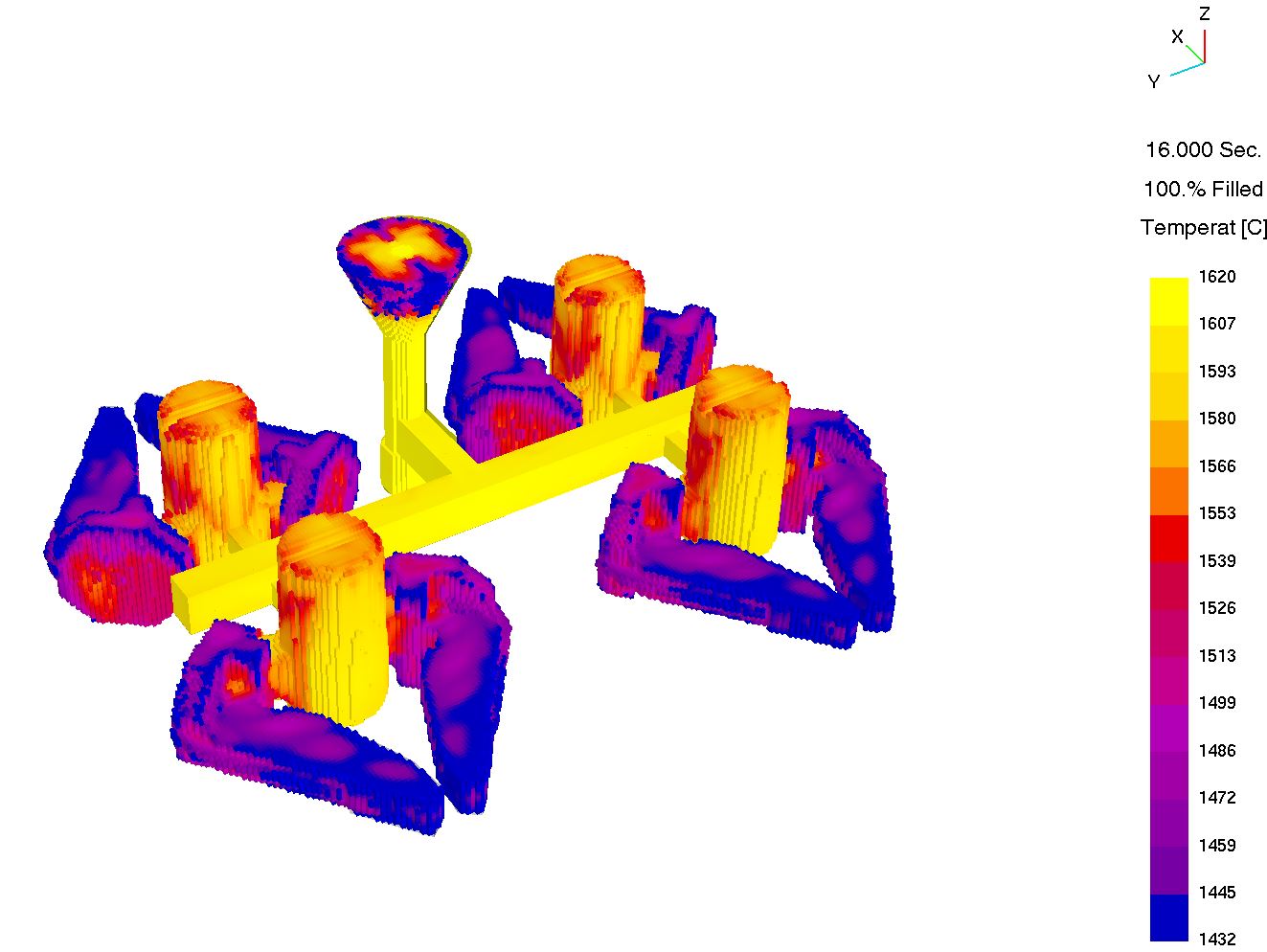

- Simulation: Filling and Solidification

- Finite Solutions Flowcast and Solidcast

- Pattern Making:

- Rapid Prototyping:

- SLA

- SLS

- 5-axis rapid machining – sand or composite material (subcontracted)

- Traditional pattern makers (subcontrated)

- Rapid Prototyping:

Moulding

- Mechanical Moulding

- Up to 1.300 x 1.000 x 800 mm and 650kg

- Hand Moulding

- Up to 1.300 x 1.075 x 1.100 mm and 650kg

- 2 Sand Mixers

- Capacity: 20 Ton/Hour

- IRIS Pattern Recognition System

- Optimized process control

Melting

#4 Induction Furnaces

- #2 Furnaces Capacity: 1Ton

- #1 Furnaces Capacity: 500Kg

- #1 Furnaces Capacity: 150Kg

Finishings

- Dedicated area for Stainless Steels

- Shot-blasting, Grinding and Welding

- Shot blasting machines

- CM and NORMFINISH

- Grinding Machines

- High frequency and Compressed air

- Heat Treatments

- In-house heat treatments

- Other activities, such has machining, coatings, surface chemical treatments, among others, can be subcontracted to FERESPE’s experienced partners.

Quality Control Equipment

- Optical Emission Spectrometers

- Destructive Testing

- Non Destructive Testing

- Hardness Control

- Samples Preparation and Metallographic Analysis