- Modeling

- PTC Creo 3.0

- 3D Scanning

- Dimensional Control

- Reverse Engineering

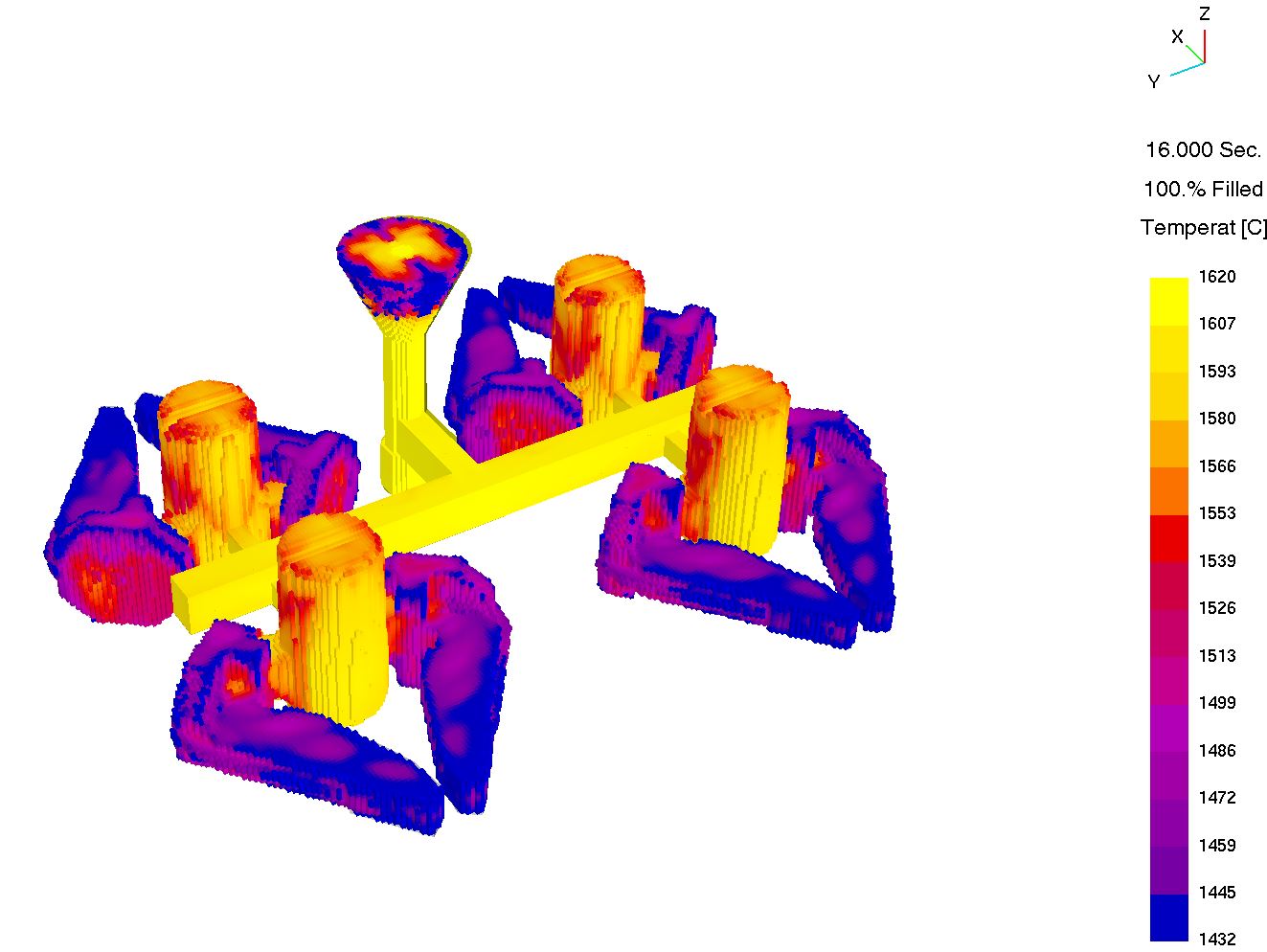

- Simulation: Filling and Solidification

- Finite Solutions Flowcast and Solidcast

- Pattern Making:

- Rapid Prototyping:

- SLA

- SLS

- 5-axis rapid machining – sand or composite material (subcontracted)

- Traditional pattern makers (subcontrated)

- Rapid Prototyping:

Moulding

- Mechanical Moulding

- Up to 1.300 x 1.000 x 800 mm and 650kg

- Hand Moulding

- Up to 1.300 x 1.075 x 1.100 mm and 650kg

- 2 Sand Mixers

- Capacity: 20 Ton/Hour

- IRIS Pattern Recognition System

- Optimized process control

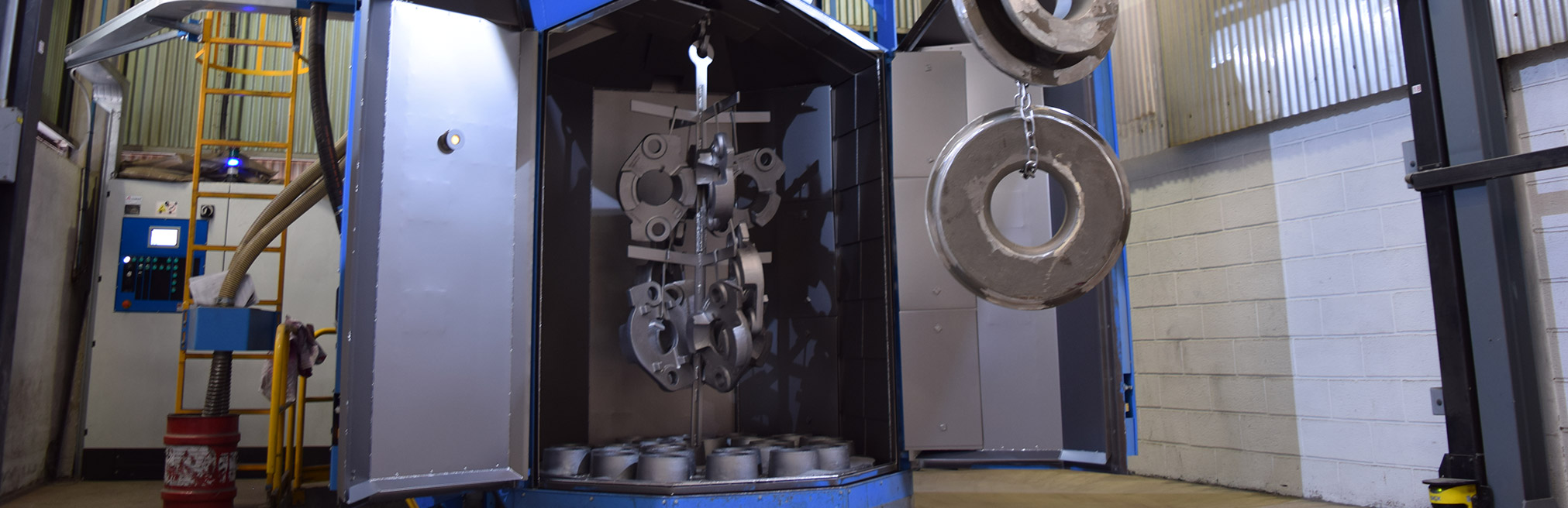

Melting

#4 Induction Furnaces

- #2 Furnaces Capacity: 1Ton

- #1 Furnaces Capacity: 500Kg

- #1 Furnaces Capacity: 150Kg

Finishings

- Dedicated area for Stainless Steels

- Shot-blasting, Grinding and Welding

- Shot blasting machines

- CM and NORMFINISH

- Grinding Machines

- High frequency and Compressed air

- Heat Treatments

- In-house heat treatments

- Other activities, such has machining, coatings, surface chemical treatments, among others, can be subcontracted to FERESPE’s experienced partners.

Quality Control Equipment

- Optical Emission Spectrometers

- Destructive Testing

- Non Destructive Testing

- Hardness Control

- Samples Preparation and Metallographic Analysis